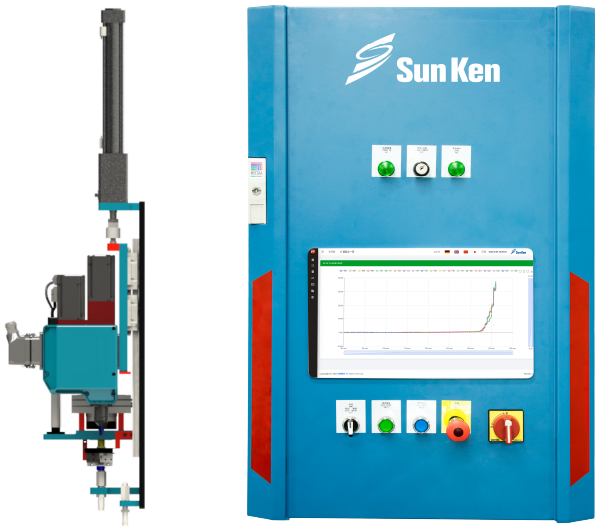

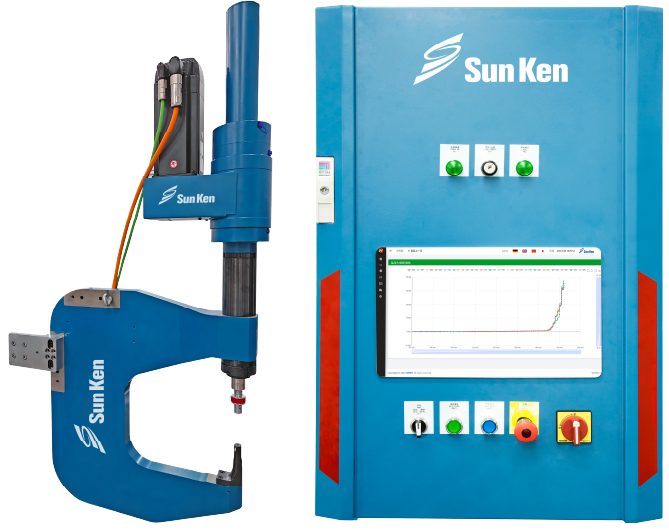

Blind Rivet /Blind Nut Joining System

Blind rivet and blind nut joining system is an advanced automated solution which is designed to accommodate a wide range of applications. It supports blind rivets with diameter range from 2.4mm to 8.0mm and blind nuts from M3 to M12, making it ideal for assembling rivets and nuts. Equipped with servo drive motor(s), the system enables data collection and analysis for enhanced operational insights. Its modular design ensures easy maintenance, and it delivers a maximum setting force of 25kN.

- Rivet range:D2.4-D8.0

- Rivet Nut range: M3-M12 (PAT. Pending)

- Suitable for the assembly of rivet nuts

- Servo drive to ensure data to be collected and analyzed

- Modular design for easy maintenance

- Setting force: 25kN

- Riveting aluminum threshold nuts

- EV Battery Pack box

- Car front & rear bumpers, and other auto parts

- Patented floating head design enables X/Y axis and angular adaptive riveting

- Adaptive sheet metal riveting

- Dual servo drive system with full-process monitoring

- Quick-change head/mandrel configuration

Technical Parameters

| Applicable rivet nut / stud | ≤M16 (rivet nut materials: stainless steel, steel, aluminium) |

|---|---|

| Applicable material thickness | ≤14mm |

| Setting force | ≤ 60kN |

| Force control accuracy | 1N |

| Displacement control precision | 0.01mm |

| Drive power | Dual Servo Motors |

| Power supply | 200V~, 50Hz/60Hz |

| Communication protocol | EtherNet/IP, ProfiNet, DeviceNet, etc. |

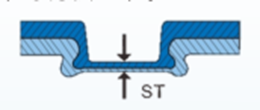

Clinching System

Under the action of external force, the special Clinching mold forces the combination of joined materials to produce material flow at the joining point, forming a plastic deformation process of mutual inlay, which is called Clinching.

- A variety of structural forms (mobile, handheld)

- High-Precision positioning

- Servo drive to ensure data to be collected and analyzed Suitable for joining the same or different materials, and the workpiece will not

positioning→preloading →pressing →forming →non-destructive testing

What is Clinching ?

Under the action of external force, the special Clinching mold forces the combination of joined materials to produce material flow at the joining point, forming a plastic deformation process of mutual inlay, which is called Clinching.

The joining point has a certain tensile strength and shear strength, which is called the joining point.

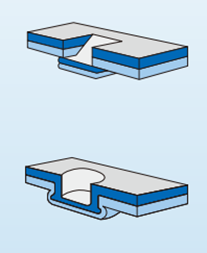

The geometry of Joining Point?

Clinching points can be either round or rectangular.

- Under the action of the round point mold, the joining metal plate undergoes internal deformation to form a round clinching point, which is a good in appearance and evenly distributed in internal stress.

- It is mainly suitable for the joining of soft materials and thin materials.

- The rectangular point clinching is a composite cutting and deformation process, which is mainly suitable for the joining of hard materials and stainless steel plates.

Technical Parameters

| System Contents | Techinical Specifications | Unit | |

|---|---|---|---|

| CNC Drives: Power Unit | Max Drive | 50 / 80 | kN |

| Max Stroke | 100 / 200(optional) | mm | |

| Max Free Speed | 250 | mm/s | |

| Max Working Stroke | 35 | mm/s | |

| Open Height | 50 / 100 / 150 | mm | |

| Depth S/M/L | 200 / 250 / 300 | mm | |

| Extra-Large Depth XL | 350 / 450 / 600 | mm | |

| C Frame | Die Support Height | 30 /50 /80 (customizable) | mm |

| Die Type | Round Die | ø3, ø4, ø5 | mm |

| ø6, ø8, ø10 | mm | ||

| Rectangular Die | St 4.3, 5, 6 | mm | |

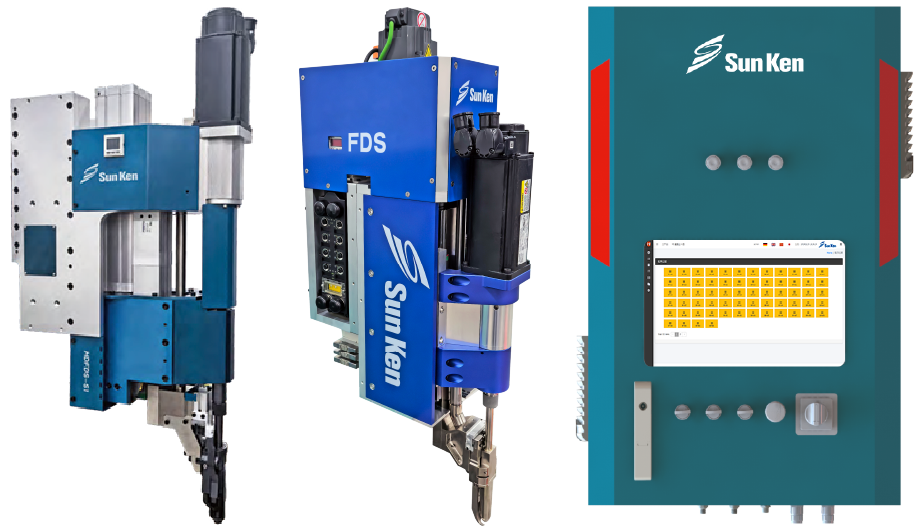

Flow Drill Screw Assembly System

Flow Drill Screw Assembly System is capable of one-sided, profile, and small-hole bonding, catering to a wide range of fastening needs.

- It excels at joining dissimilar materials of varying thicknesses, and its dual servo drive ensures complete monitoring for high-precision, stable operation.

- Its high rewind torque delivers excellent airtightness and vibration resistance, while the flexible spindle design adapts to various working environments.

- The system also features a quick-change batch head to enhance operational efficiency.

- Its primary applications include joining dissimilar steel and aluminum car bodies, making it widely utilized in the automotive industry.

- Single-sided joining process (make it possible to join profile s and small holes)

- Assemble different materials of different thicknesses.

- Dual servo drives, complete process monitoring.

- High loosening torque, good air tightness, strong vibration resistance.

- Spindle is flexible and the bits can be changed quickly.

Riveting at steel and aluminum multi-layer sheet on car body.

Technical Parameters

| Model No. | HDFDS-S1(single servo) | HDFDS-S2(dual servo) |

|---|---|---|

| Torque | ≤15Nm | ≤15Nm |

| Free Pressure | Under air pressure at 0.6MPa ≤3600N | ≤3600N |

| Nozzle Pre-pressure | Under air pressure at 0.6MPa ≤1400N | ≤1400N |

| Setting Time | 1.8s | 6s |

| Drive System | Single Servo Motor | Dual Servo Motors |

| Power Supply | 200V~, 50Hz/60Hz | |

| Communication Protocol | EtherNet/IP, ProfiNet, DeviceNet, CC-Link | |

Actuating Unit

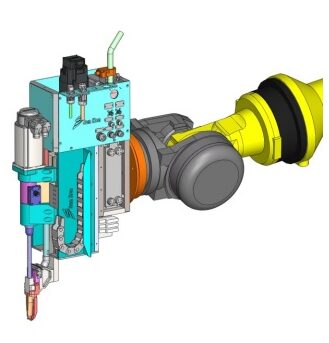

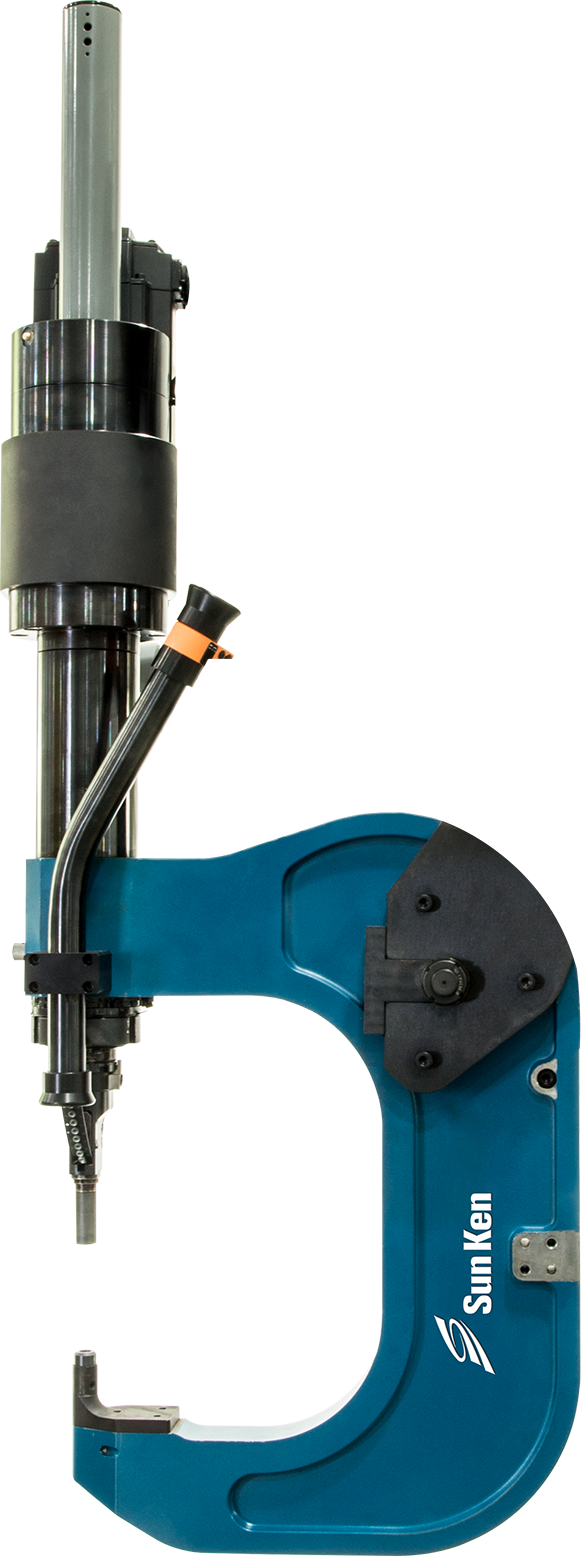

Self-Pierce Riveting System (PAT. Pending) employs advanced servo riveting technology to deliver highly efficient and precise riveting operations.

With a maximum fastening force of 85kN and a cycle time of 2–3 seconds, it significantly reduces the manufacturing line’s takt time.

- High joining strength

- The process is simple which completed in one step.

- Servo drive to ensure the data to be collected and analyzed.

- Multiple feeding methods (strips, vibrating plates) to meet the actual needs of customers.

- Servo motor for power drive

- Max setting force: 85kN

- The assembly cycle time is 2~3s to meet the CT requirements of all customers

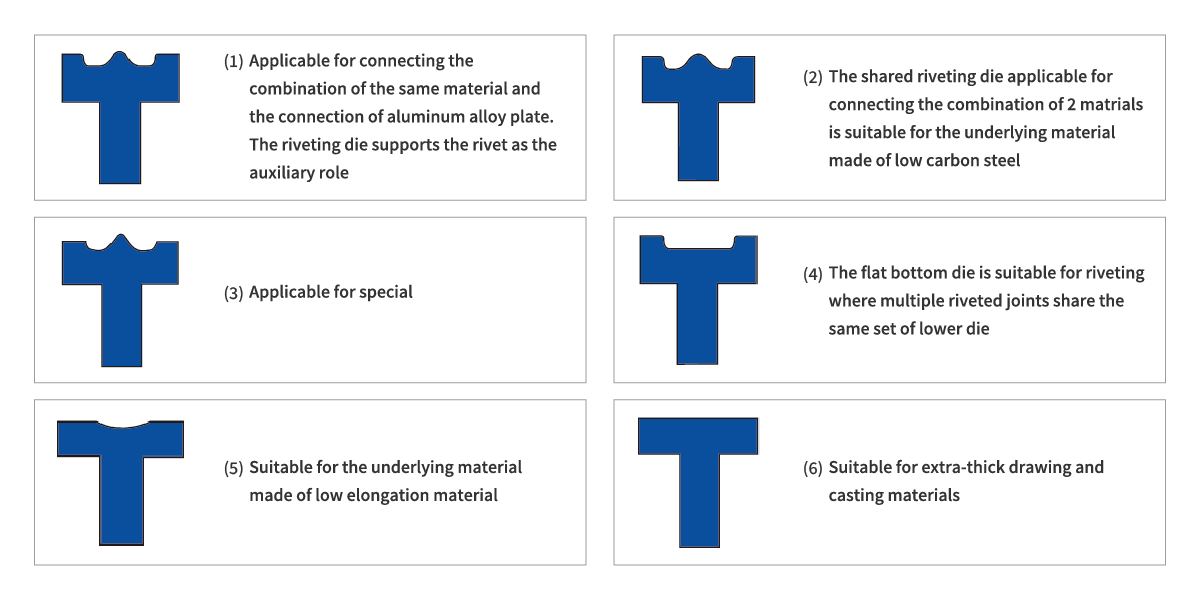

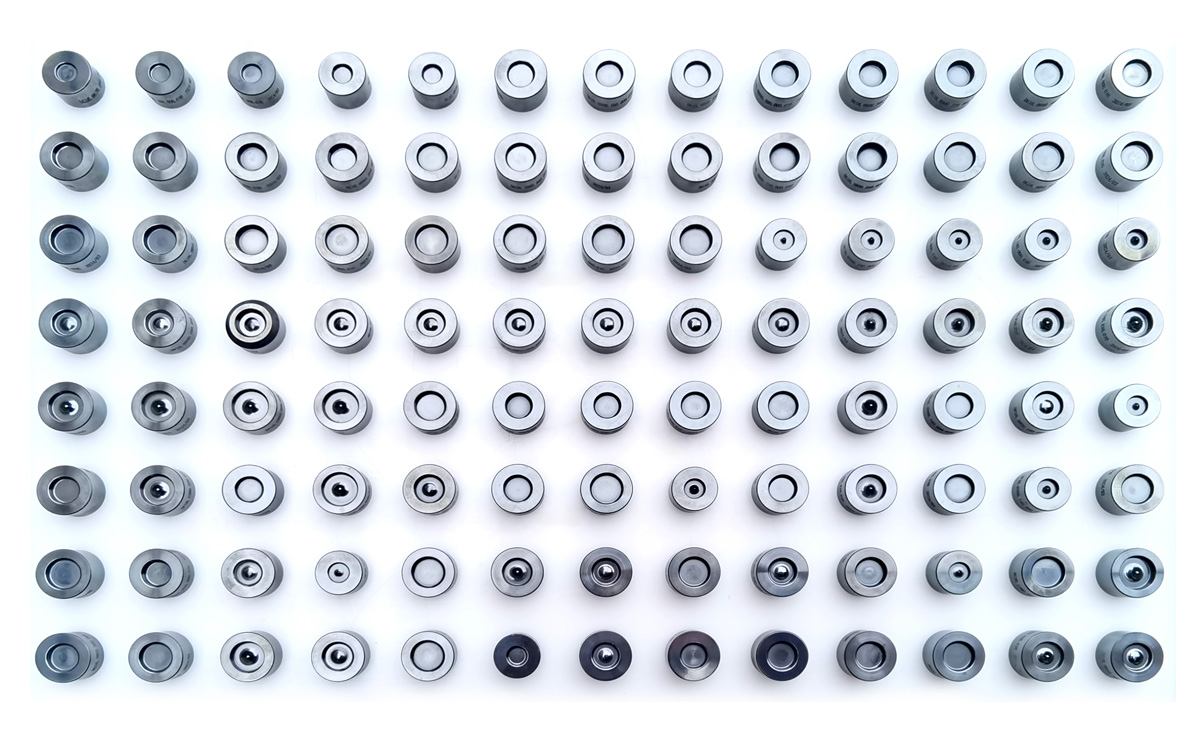

Dies

- High joining strength

- The process is simple which completed in one step.

- Servo drive to ensure the data to be collected and analyzed.

- Multiple feeding methods (strips, vibrating plates) to meet the actual needs of customers.

- High lifespan, for long durability

- High adaptability

- High-Precision positioning

| Applicable Rivets | ø3.3 /ø5.5, Optional: ø4.0/ø5.3/ø6.5 |

| Material Strength | ≤1600Mpa |

| Workpiece Layers | 2-4 |

| Setting Force | ≤85kN |

| Riveting accuracy | 0.01kN |

| Riveting Speed | ≤250 mm/s |

| Speed Adjustment Accuracy | 1mm/s |

| Displacement Control Accuracy | 0.01mm |

| Drive System | Servo Motor |

| Power Supply | 200V~, 50Hz/60Hz |

| Standard Lap Size | ø3.3 / ø4.0, 16mm |

| ø5.3 /ø5.5 /ø6.5, 18mm | |

| Depth | 150mm – 1200mm |

| Maximum Opening Size | 60mm – 250mm |

| Communication Protocol | EtherNet/IP, ProfiNet, DeviceNet, CC-Link, etc |

| Fastener Feeding Method | Manual, Vibration Bowl, Tape, Magazine |

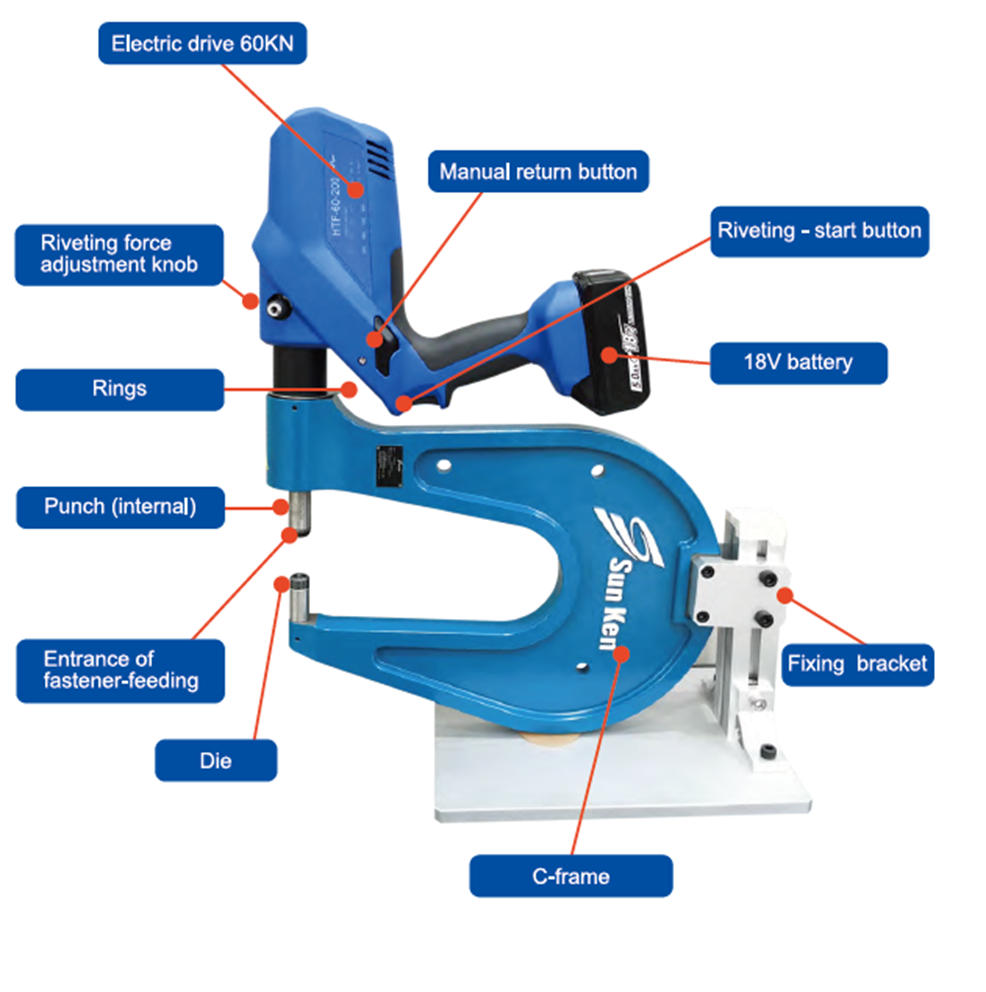

Handheld Self-Pierce Riveting Tool (HTF)

- Easy to Carry

- Easy to use

- The joining force is adjustable

- Work with C-frame with different depth

- C-frame standard depth: 35mm/140mm/200mm

- Pressure range: 60kN, 80kN

- Joining force adjustment: Pressure can be modified by tightening or loosening with a hex wrench・Flexible fastener-feeding options:

- (manual feeding, belt feeding or custom solutions available upon request.)

| Project | Specification | Technical Specification |

|---|---|---|

| Maximum driving force | 60/80 kN |

| Opening height | 18/35 mm | |

| Depth | 35/140/200 mm | |

| Duty cycle time | 14(stroke-related) s | |

| Feeding system: belt (manual/automatic) | Rivet diameter | Φ3/Φ5 mm |

| Feeding head | Φ3/Φ5 mm | |

| Power demand | Lithium battery supply | 18/3 V/Ah |

| Charging time | 22 min | |

| Environmental requirements | Operating temperature | 15/40 ℃ |

| Storge temperature | 10/50 ℃ | |

| Relative humidity | 10/95 % |

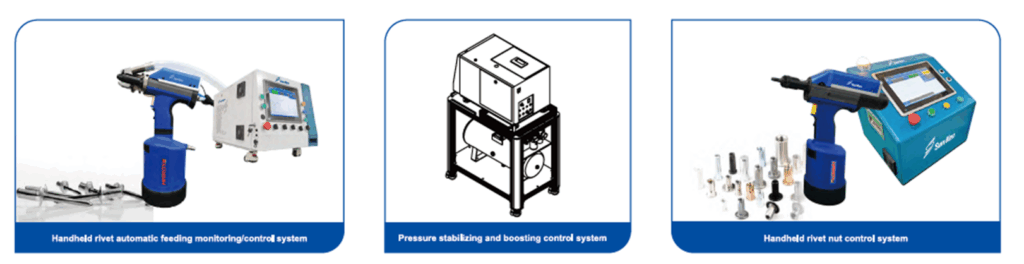

Automatic Fastener Feeding System

- When used with dedicated fastening tools, the system supports a wide range of torque settings to accommodate various fasteners.

- It can be configured for feeding and installing fasteners of different shapes and sizes. Additionally, we offer automatic feeding systems for customized products with special specifications.

- Available for all rivets/nuts feeding including blind rivets, blind nuts, blind stud, self piercing rivets, flow drill screws, etc.

Handheld Blind Riveting System

- Handheld Blind Riveting System is designed to support a wide range of rivets while ensuring reliable joint formation, further enhanced by the optional installation of a pressure sensor. With a productivity rate of up to 30 rivets per minute and a modular design for easy maintenance, it delivers efficient and stable operation. Real-time monitoring and data collection capabilities optimize process control, while the system’s fast rivet feeding time of under 2 seconds ensures seamless integration into assembly lines. Its ergonomic handheld design makes it ideal for on-site use across various industries, particularly in automotive manufacturing.

- Wide Rivet Compatibility: Compatible with steel rivets (2.4–8 mm) and aluminum rivets (2.4–10 mm).

- Pressure Sensor (Optional): Enhances joint reliability by ensuring optimal riveting pressure.

- High Productivity: Capable of installing up to 30 blind rivets per minute, maximizing efficiency.

- Mandrel Recovery System (Optional): Enables mandrel inspection and counting for quality control.

- Modular Design: Allows for easy maintenance and system customization.

- Real-Time Monitoring & Data Collection: Records production settings, process results, and provides real-time error feedback.

- Fast Rivet Feeding: Rivet supply time of less than 2 seconds, meeting takt time requirements.

- High Durability: Equipped with a robust rivet feeding tube designed for long-distance transportation and extended operational life.

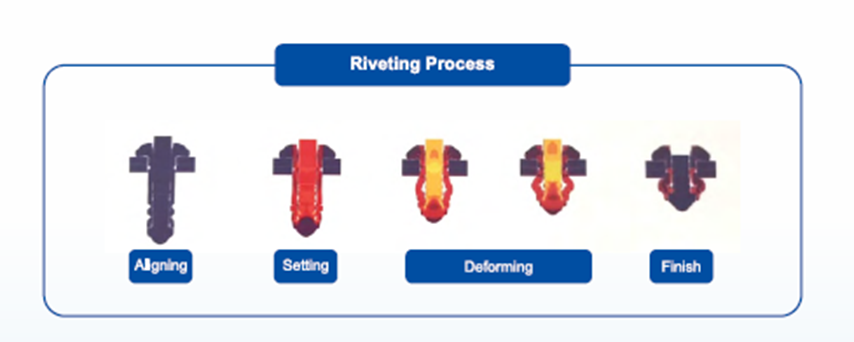

Blind Riveter

Working on one-side only

The special feature of blind rivet joining is that only work on one side of the workpiece, but screw fastening, percussion and pressing joining, etc. ) and work on both side.

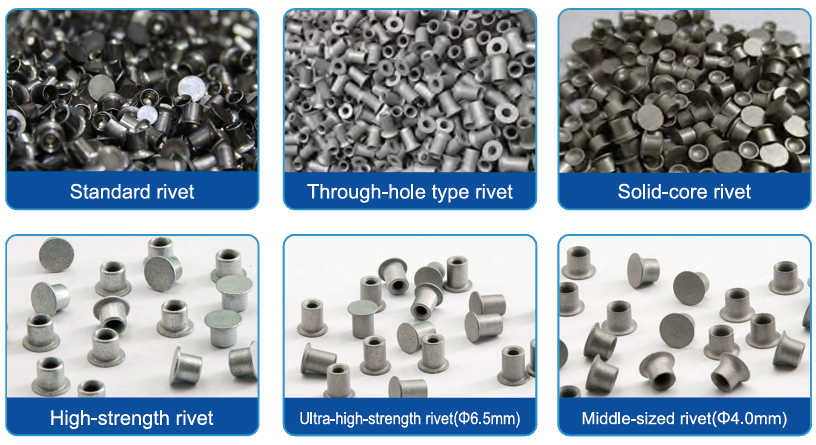

Blind rivets- High strength, vibration resistant

Blind rivets are composed of two parts: The rivet body and the mandrel. During setting, jaws pull the mandrel, press the rivet body into position. The mandrel will break at the preset breakpoint (target breakpoint) and being collected through negative pressure tube. According to the application conditions, the remaining part of the mandrel in the rivet body will provide high-strength suitable force, as well as high tensile and shear resistance.

Blind rivets-suitable for all applications

Blind rivets are available in different designs, materials, forms, lengths and colors. Depending on the application of the blind rivet, the customer can choose from standard parts available from stock or specially designed blind rivets being developed for specific applications.

Blind Riveter

| Model | Blind rivets | Weight | Operating air pressure | Stroke | Setting force |

|---|---|---|---|---|---|

| mm | kg | bar | mm | kN (at 6bar) | |

| HDPA-4T | 2.4-3.2 | 1.3 | 5-7 | 15 | 4.2 |

| HDPA-5T | 2.4-5.0 | 1.6 | 5-7 | 18 | 11 |

| HDPA-6T | 3.2-6.4 | 1.9 | 5-7 | 25 | 18 |

| HDPA-8T | 3.2-6.4 | 2.0 | 5-7 | 19 | 23 |

Automatic Rivet Supply System

| Terms | Technical Specification |

|---|---|

| Pulling Force | 22kN/0.6 MPa (Max is adjustable according to air pressure) kN |

| Stroke | 10 (Max is adjustable) mm |

| Suitable blind rivets range | Φ3.2~Φ6.4 mm |

| Tool weight | 2.5 ㎏ |

| Cycle time | 3-5 (include riveting process) s |

| Power supply | AC220/50 V/Hz |

| Air pressure | 0.5~0.7 Mpa |

| Working temperature | 0~45 ℃ |

| Storage temperature | -10~50 ℃ |

| Relative humidity | 10~95 % |

| Noise level | <75 dB(a) |

| Protection | IP54 |

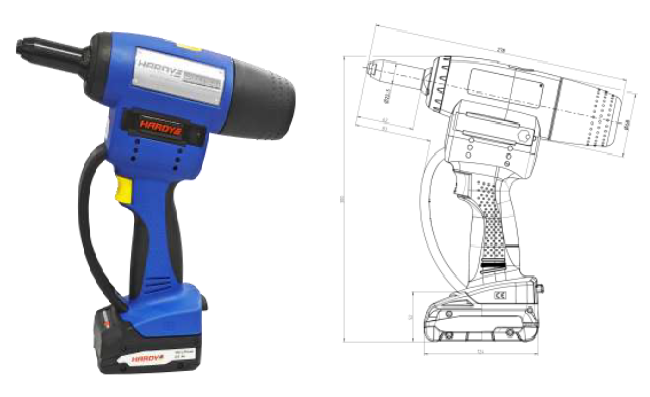

HDPA-6TE-B1 Cordless Blind Rivet Tool

- Completed Set: includes tool, four standard nosepieces, one 100V charger, and one 2.0Ah battery

- Maximum Pulling Force: 20 kN

- Weight: 2.1 kg (with battery installed)

- Drive: Brushless DC motor

- Stroke: 25 mm

- Dimensions: L278 mm × H300 mm

- Nosepieces: 17/32, 17/36, 17/40 and 17/45, additional jaw pusher for smaller blind rivets.

- The high pulling force of 20 kN allows compatibility with rivets of all materials.

- Supports rivet diameters up to 6.4 mm (max. mandrel 4.3mm).

- Ergonomic design to reduce operator fatigue. Optional auto-reverse function shortens the retraction process for improved efficiency.

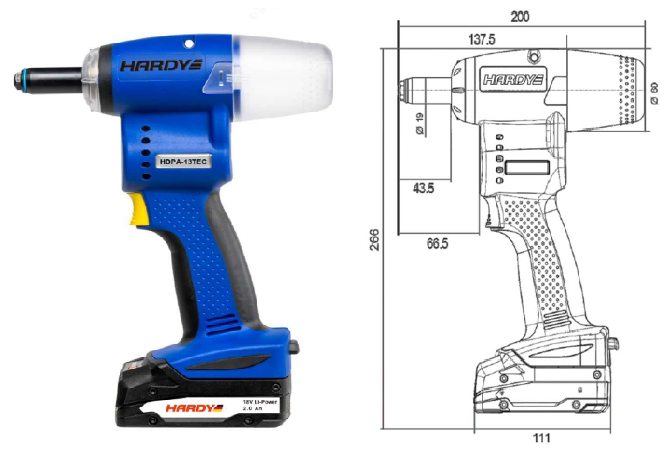

HDPA-13TEC Cordless Blind Rivet Tool

- Completed Set: includes tool, four standard nosepieces, one 100V charger, and one 2.0Ah battery

- Weight: 900g (without battery), 1.3kg (with battery)

- Pulling Force: 10,000N

- Drive: Brushless DC Motor

- Supplied Accessories: Nose pieces 17/27 (green), 17/29 (yellow), 17/32 (red), 17/24 (blue)

- Workpiece Range: Suitable for blind rivets up to 5mm in diameter for all materials, and up to 6mm in diameter for aluminum (maximum mandrel size 3.5mm).

- Wide Working Range: Supports long rivets with a powerful 10,000 N setting force and a 25 mm stroke.

- One-Tap Function Activation: Boosts work efficiency with a short setup cycle—just tap to operate.

- Transparent Used Mandrel Collection Container: Allows easy monitoring of used mandrel fill level at a glance.

- Work Light for Precise Positioning: Ensures accurate setting even under any lighting conditions.

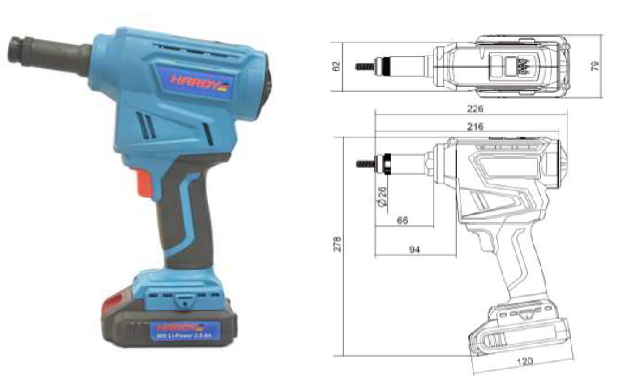

HDPA-20TE-1 Cordless Blind Nut Tool

- Completed Set: includes tool, 4 standard mandrel sets, one 100V charger, and one 2.0Ah battery

- Specifications: S type (stroke setting) / FS type (pulling force / stroke setting)

- Weight: 2.11 kg (with battery) / 1.74 kg (without battery)

- Stroke: 10 mm

- Pulling Force: Up to 25,000 N

- Applicable Nut Range: M3-M12

- Noise Level: 76 dB(A)

- High pulling force of 25,000 N enables reliable installation of rivet nuts across a wide range of materials.

- The setting panel is positioned on the top of the tool for easy visibility and minimal interference during operation.

- A brushless motor ensures maintenance-free, long-lasting performance.

- Equipped with an LED light in front of the tool to enhance visibility during positioning in any dark working environments.

Self Piercing Rivets

More than 300 types of riveting dies in all

Custom made riveting dies