Our Business

Since our founding in 2013, we have been expanding our business, focusing on the production bases of automotive manufacturers globally and delivering Made-in-Japan products to customers in various industries such as automotive, aerospace, electrical, construction machinery, and industrial equipment sectors. Moving forward, we will continue to provide high-level solutions to both Japanese and foreign companies worldwide, offering the spirit and technology of Japanese NOMODZUKURI.

We have established a robust framework to swiftly deliver optimal solutions to globally expanding clients by optimizing its proprietary global production network. This enables us to stay ahead of market trends and dynamics worldwide.

Development & Production Sites:

•Japan (Osaka)

•Germany (Meinerzhagen)

•China (Guangzhou, Shanghai)

SUN KEN is advancing its capabilities in joining dissimilar materials – especially aluminum and ultra-high-strength steel (giga steel) up to 2200 Mpa – to meet the growing demand for lightweight products.

Through the development of proprietary riveting systems and specialized rivets, we continue to tackle advanced technical challenges and evolve our solutions every day.

Solving our customers’ challenges with proven technological expertise – this is the mission that drives SUN KEN.

-1-1024x700.jpg)

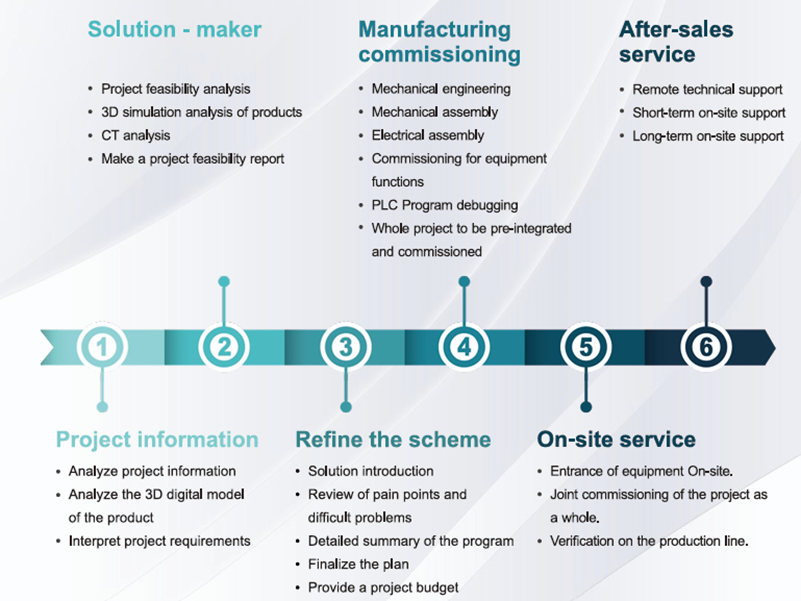

At SUN KEN, we provide not only standard products but also customized solutions tailored to our customers’ specific needs – all delivered under our ISO 9001 and ISO 14001 certified quality and environmental management systems. We consistently implement the following processes throughout the entire product lifecycle.

We is committed to delivering dependable solutions that support long-term performance, sustainability, and customer satisfaction.

We are committed to creating and delivering value from the customer’s perspective, responding precisely to their evolving needs.

We pursue sustainable growth and maximize customer satisfaction through three core pillars:

•Driving technological innovation

•Continuously improving production efficiency

•Delivering market-leading products and services

By solving our customers’ challenges with dedication and expertise, we aim to be a trusted partner in shaping the future – together.

Industries and Application Examples:

- Shipbuilding Industry

- Railway Industry

- Aerospace Industry

- Automotive Industry

- Construction Industry

- Vehicle Assembly Work

- Equipment Assembly Work

- Construction Work

- Inspection and Maintenance Work

- Grinding Work

- Polishing Work